- Home Page

- Company Profile

-

Our Products

- Cutting Machine

- Concrete Cutter Machine

- Plate Compactor

- Ring Making Machine

- Power Trowel

- Bending Machine

- Earth Rammer

- Straightening Machine

- Industrial Pump

- Road Roller

- Paver Machine

- Screed Vibrator

- Ride On Roller

- Truss Screed

- Batching Plant

- Vibratory Roller

- Threading Machine

- Construction Roller

- Pallet Truck

- Manual Stacker

- Bull Floater

- Concrete Mixer

- Suspended Platform

- Concrete Bucket

- Concrete Trolley

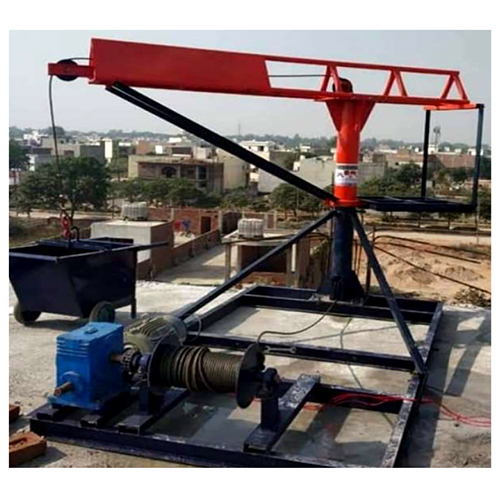

- Construction Hoist

- Contact Us